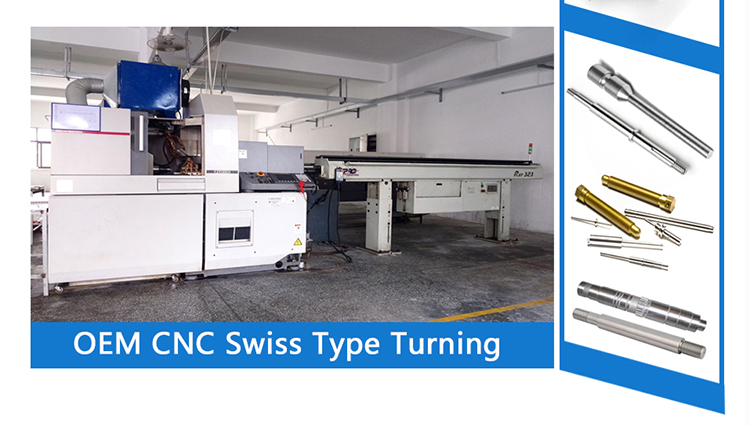

CNC Turning

Laser Cutting Anodized Treatment Aluminum 3mm thickness link arm for Connection Adjustment Applications

Fabrication Capcibility :

Aluminum Alloy

1012,2024,5052,6061,6063,7075,ADC12, A380, ALSI9CU3, ALSI12FE, A390, ADC14, etc

Brass Alloy

Tinbronze, Germansilver, White copper, Red copper, Brass, Bronze, Copper, etc

Steel Alloy

L1214,L1215,45C, A3, Q235, Q345, 16Mn, 40Cr, 20Cr, 40CrMo, 20CrNiMo, 40CrNiMo, etc

Stainless Steel Alloy

SUS303, SUS304, SUS316, etc

Plastic

POM, ABS,PC,PA,PE

Anodizing ( anodized)

Anodizing ,Hard anodizing, Double anodizing

Plating ( coating)

Nickel plating, Zinc coating, Chrome plating, Silver plating, Gold plating, Bright Zinc Plated, Plating of Silver, Copper, Zinc, Nickel, Glod, ,Passivate etc

Polishing

Burnishing, Sand casting, Polishing, Sand blast , etc

Painting (powder coating)

Phosphate coating, powder coating, etc

Fabrication Process:

Aluminum Extrusion, Turning, Millling, Engraving, Grinding, Cutting, Stamping, Boring, Broaching, Drilling, Rolling, Punching, Lasering ,

Tolerance:

+/-0.02mm( iron parts), +/-0.01mm( Aluminium, brass parts)

Surface roughness:

0.2-1.6

QC control:

IQC Incoming quality control, IPQC In-process quality control, Outgoing quality control. 100% inspection on critical dimensions before shipping

Testing Tools:

Projecting profile, Roughness tester, Hardness tester, Concentricity tester, 2D projector, Digital Micrometers, Salt spray tester, all kinds of gages

Machine Tools:

CNC Turning Center/ CNC Turning machines/ CNC Milling Center/ 4-axis CNC machine/ 5-axis CNC machine , Punch machine, EMD machine, etc.

General Information :

Company Name

Dongguan Beigeng Hardware Electronic Technology Co., Ltd.

Foundation Year

2010

Address

No.2 Junpeng Road,Qingyunlin Industrial Area, Tangxia Town, Dongguan city

Tel&Fax

0086-769- 8988 7380 / 0086-769- 8778 1961

Company Structure :

Number of Workers

100-150

Number of Engineers

10

Number of QC:

12

Turnover 2013

Over USD Dollar 2 Millions

Main Market(Client)

USA , Japan, Germany, Canada, Italy, Unite kingdom

Factory Size (sqm)

2000 square meter

Working Hours

8 hour per day

After Service:

Management of Customer Complaints

Highly Attention and Quick Processing Result in 24hours

Managing Product Returns

With quality problem or deviation from drawings

Shipment of Samples

By DHL,Fedex,UPS, TNT,EMS

Warranty

Replacement at all our cost for rejected products

Q. What is the shipping ?

A:By express(FedEx, UPS, DHL, TNT, EMS, etc...),By Air,by shipping.

Q. How do I pay for the order?

A.The common payments are T/T(Telegraphic Transfer),western union ,

Q. I have an idea for a new product, but don't know if it can be manufactured. Can you help?

A. Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Q. Can I test some samples before order?

A. Yes, can make samples for you before order, but you should pay sample charges.

Q. What type of material is best for my design/component?

A. Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material.

Q. What type of processing technic you can offer and what type of processing technic do I need?

A.We can offer processing technic of CNC turning parts, CNC broaching, CNC milling parts, CNC drilling parts, etching machining, chemical machining, laser machining, Wire EDM, CNC shaving parts, CNC grinding parts, CNC boring parts, CNC pulling parts and so on, we will design the best solution for you base on your drawing, material and its precision demand.

Q.Ok, I've decided to go ahead with my project. How long will it take to get my parts?

A.Normally it will take abou 3 weeks to finish, but it also depens on your requst and order quantity.